Get professional advice and find out which roofing solution is right for your building.

The trapezoidal profile is a durable metal roofing material manufactured using the cold-rolling method. Its design provides high rigidity and the ability to withstand heavy snow and wind loads. The special shape of the side edges protects joints from moisture penetration, ensuring the roof’s long service life.

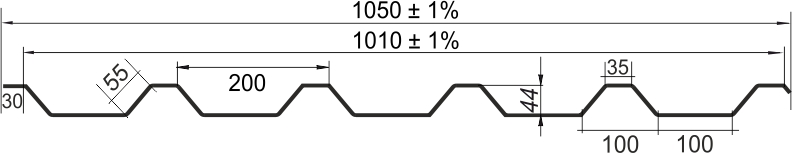

PP45 – a profile with deeper and larger ribs, providing exceptionally high load-bearing capacity. It is ideal for roofs in regions with heavy snow and wind loads, as well as for large public and industrial buildings.

The trapezoidal profile is a durable metal roofing material manufactured using the cold-rolling method. Its design provides high rigidity and the ability to withstand heavy snow and wind loads. The special shape of the side edges protects joints from moisture penetration, ensuring the roof’s long service life.

PP45 – a profile with deeper and larger ribs, providing exceptionally high load-bearing capacity. It is ideal for roofs in regions with heavy snow and wind loads, as well as for large public and industrial buildings.

LEBENS manufactures and sells trapezoidal profiles both wholesale and retail. Production in Latvia allows for fast fulfillment of orders of any volume, with the option to purchase directly at the factory in Riga or arrange delivery throughout Latvia.

Material types

PURMATT – GreenCoat® Pural BT

Top-quality steel with a 50 µm paint coating, produced using bio-based technology with rapeseed oil. Provides excellent resistance to UV radiation (Ruv5), corrosion (RC5+), scratches, and weathering. Suitable for roofs, facades, and other metalwork, maintaining excellent formability down to –15 °C. Technical warranty – 50 years, aesthetic warranty – 25 years.

ULTRAMAT – Granite® Ultramat (ArcelorMittal)

Premium painted steel for roofing with a matte textured surface and <5 GU gloss. Coating thickness: 35 µm, zinc layer 275 g/m², steel thickness ≥ 0.50 mm. Excellent properties: resistance to temperature changes, scratches, color stability, flexible formability down to –15 to –20 °C, RC4 and RUV4 durability. Provides up to 40 years technical warranty and 20 years aesthetic warranty.

PE matt – Polyester matt

The most popular metal roofing coating with a uniform matte finish. Steel sheets are coated with zinc, primer, and a polyester decorative layer, which provides color and protection against external factors. Coating thickness: 30 µm, steel thickness ≥ 0.45 mm. Technical warranty – 30 years. Advantages: good price-to-quality ratio, weather resistance, and aesthetic appearance in various colors.

PE – Glossy Polyester – the most classic and affordable roofing coating type with a smooth, shiny surface.

The steel sheets are coated with a zinc protective layer, primer, and a polyester decorative coating, which ensures color retention and protection against external effects. Coating thickness: 25 µm, steel thickness: ≥ 0.45 mm. Technical warranty: 20 years.

Zn – Zinc – A classic steel roof coating with a hot-dip galvanized protective layer. Provides corrosion resistance, is cost-effective, and widely available. Zinc coating weight: ~275 g/m². Thickness: 0.50 mm. Advantages: good protection at a low cost, suitable for small and medium-sized buildings.

AlZn – Aluzinc – Steel sheets coated with an aluminum-zinc alloy that combines the best properties of both metals.

Available thicknesses: 0.45 mm and 0.50 mm. Coating weight: 150 g/m². Provides significantly higher corrosion resistance compared to standard zinc coating. Advantages: excellent corrosion resistance, ideal for aggressive environments and long-term solutions.

Color: RR 23

Product code: PURMATT, PE matt, PE

Color: RR 32

Product code: PURMATT, PE matt, PE

Color: RR 2H3

Product code: PURMATT

Color: RR 887

Product code: PURMATT

Color: RAL 9005

Product code: PE matt

Color: RAL 7016

Product code: ULTRAMATT, PE matt, PE

Color: RAL 8019

Product code: ULTRAMATT

Color: RAL 8017

Product code: ULTRAMATT, PE

Color: RAL 3005

Product code: PE

Color: RAL 3009

Product code: PE

Color: RAL 8004

Product code: PE

Color: RAL 6020

Product code: PE

Color: RAL 6005

Product code: PE

Color: RAL 7000

Product code: PE

Color: RAL 7035

Product code: PE

Color: RAL 7004

Product code: PE

Color: RAL 9006

Product code: PE

Color: RAL 9007

Product code: PE

Color: RAL 9010

Product code: PE

Color: RAL 1015

Product code: PE

Color: AlZn

Product code: AlZn

Color: Zn

Product code: Zn

LEBENS ir Latvijas jumtu un fasāžu materiālu ražotājs ar vairāk nekā 30 gadu pieredzi.

Mēs ražojam metāldakstiņus, profila loksnes un lietusūdens noteksistēmas, nodrošinot augstu kvalitāti, uzticamību un ilgmūžību katram objektam.

Mūsu uzņēmums piedāvā plašu jumta segumu klāstu, pilnu pakalpojumu spektru un individuālu pieeju katram klientam — no konsultācijas līdz gatavam risinājumam.

LEBENS produkcija atbilst Eiropas kvalitātes standartiem un ir pieejama mūsu filiālēs visā Latvijā.

Profesionāla pieeja, modernas ražošanas tehnoloģijas un ilggadēja pieredze padara LEBENS par uzticamu partneri gan privātmāju, gan industriālo objektu būvniecībā.

Here you will find answers to frequently asked questions about roofing types, installation and maintenance. If you don't find the information you are interested in - feel free to contact us!

Here you will find answers to frequently asked questions about roofing types, installation and maintenance. If you don't find the information you are interested in - feel free to contact us!

Click profiles are a modern alternative to rolled profiles – they can be installed quickly without special tools. The panels simply "click" together, forming a tight connection. Classic rolled profiles are connected mechanically and are more commonly used for more complex roof structures.

Yes, a metal roof is ideal for Latvia's changing climate – it can withstand rain, snow, frost and temperature fluctuations.

Lebens metal roofs come with a warranty of up to 50 years, depending on the material used and the quality of the surface coating.

Metal roofs are lightweight, durable, fireproof, long-lasting and low-maintenance – unlike bitumen or ceramic tiles.

Yes, Lebens offers customized solutions for complex architectures, adapting materials and details to specific projects.

Yes, we deliver metal roofing throughout Latvia.

Roof elements, drainage systems, ventilation solutions, safety and connection details – all in one place.

Use the roof calculator or contact us – we will provide you with an accurate material calculation based on the square footage of your roof.

Your application is on its way to our customer service specialist.

We will contact you soon. Have a nice day!