Trapezoidal profiles

GreenCoat PURMATT (SSAB)

GENERAL INFORMATION

GreenCoat® Pural BT coated steel offers a wide range of shades inspired by Nordic nature. The coating uses Swedish rapeseed oil and other renewable raw materials. SSAB has extensive experience in using biotechnology (BT) in GreenCoat® products.

GreenCoat Pural BT provides the highest durability for roofing applications, such as standing seam and profiled metal tiles, making it widely used in roofing metalwork. GreenCoat Pural BT with metallic, satin, or standard finishes is also used for manufacturing high-quality facade products, such as sandwich panels and cassettes.

The GreenCoat® Pural BT steel coating is optimized to withstand weather exposure, ensuring the highest UV resistance (Ruv5 for the matte version) and corrosion resistance (RC5+ class). The product has excellent scratch resistance and is easy to process during manufacturing. GreenCoat® Pural BT has outstanding forming properties, allowing complex bending work at temperatures down to -15°C, enabling year-round work at lower costs.

GreenCoat® Pural BT complies with the REACH regulation and contains no chromates.

| Technical warranty | 50 years |

| Aesthetic warranty | 25 years |

MATERIAL ADVANTAGES AND PROPERTIES

Bio-based Technology (BT) — the GreenCoat® coating thickness is 50 µm. The reverse side of the sheet has a two-layer coating to provide corrosion resistance for the final product. The coating also ensures good adhesion properties for adhesives and foams; however, compatibility should be tested in each case separately. The nominal thickness of the reverse side coating is 12 µm.

MATERIAL TECHNICAL CHARACTERISTICS

| Gloss | < 5 |

| Minimum internal bending radius | 1 x sheet thickness |

| Scratch resistance | 40 N |

| Lowest forming temperature | -15 °C |

| UV radiation resistance | RUV5 |

| Corrosion resistance | RC5+ |

| Stain resistance | Very good |

| Maximum operating temperature | 100 °C |

| Fire classification, EN 13501-1 | A1 s1 d0 |

| Coating thickness | 50 μm |

| Coating structure | Textured and wrinkled |

| Steel designation | S280GD, S320GD, S350GD, DX51D |

| Zinc coating | 275 g/m2 |

| Minimum steel thickness | 0.50 mm |

MAIN COLOR CHART

-

RR 23 PURMATT (0.6mm)

RR 23 PURMATT (0.6mm) -

RR 2H3 PURMATT

RR 2H3 PURMATT -

RR 887 PURMATT

RR 887 PURMATT -

RR 23 PURMATT

RR 23 PURMATT -

RR 32 PURMATT

RR 32 PURMATT

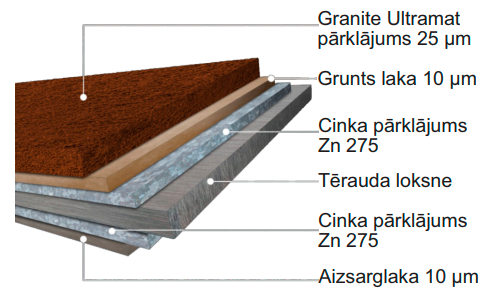

Ultramatt (Arcellor)

GENERAL INFORMATION

Granite® Ultramat is the latest addition to the pre-painted steel product line of ArcelorMittal Granite®, used for building exteriors. Granite® Ultramat is specifically designed for roofing applications. Thanks to its high quality and flexible coating system, it offers several advantages compared to standard Granite® Deep Mat and competing products.

| Perforation and delamination warranty | 40 years |

| Aesthetic warranty | 20 years |

MATERIAL ADVANTAGES AND PROPERTIES

- Durability

- Flexibility at low temperatures

- Surface toughness

- Resistance to cold storage

- Color stability

| Gloss | < 5 GU |

| Scratch resistance | ≥ 2 kg |

| Crack resistance (T-bend) at 0°C, -10°C, -20°C | ≤ 2T |

| UV radiation resistance | RUV4 |

| Corrosion resistance | RC4 |

| Coating thickness | 35 μm |

| Zinc coating | 275 g/m2 |

| Minimum steel thickness | 0.50 mm |

MAIN COLOR CHART

-

RAL 7016 ULTRAMAT

RAL 7016 ULTRAMAT -

RAL 8019 ULTRAMAT

RAL 8019 ULTRAMAT

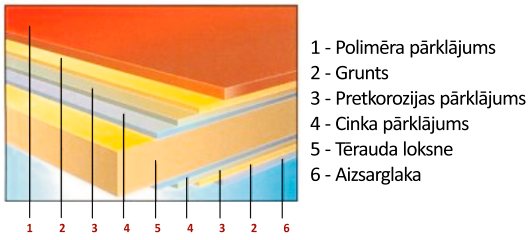

Polyester Matte (PE Mat)

GENERAL INFORMATION

Among metal roofing products, metal with a polymer coating has gained the greatest popularity. For its production, steel sheets are used, which are coated on both sides with a protective metal layer, a primer layer, and a decorative polymer coating. The final layer gives the product color and texture, as well as protects it from external factors.

| Perforation warranty | 30 years |

| Delamination warranty | 10 years |

MATERIAL ADVANTAGES AND PROPERTIES

| Type and mass of metal coating on both sides | Z 225-275 [g/m²] / ZM 100-140 [g/m²] |

| Environmental classification according to EN ISO12944-2 | C3 |

| Coating system | 2-layer |

| Organic coating thickness, side A | 30 [µm] |

| Reaction to fire | A1 |

| Resistance to external fire | B roof (t1), B roof (t2), B roof (t3) |

MAIN COLOR CHART

-

RAL 7016 MATT

RAL 7016 MATT -

RAL 9005 MATT

RAL 9005 MATT -

PE RR 23 MATT

PE RR 23 MATT -

PE RR 32 MATT

PE RR 32 MATT

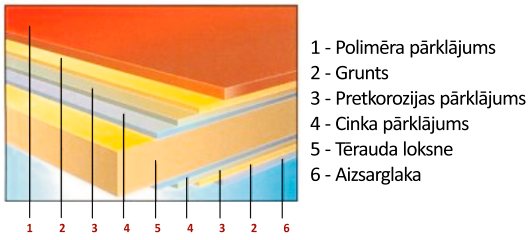

Polyester Glossy (PE)

GENERAL INFORMATION

Among metal roofing products, metal with a polymer coating has gained the greatest popularity. For its production, steel sheets are used, which are coated on both sides with a protective metal layer, a primer layer, and a decorative polymer coating. The final layer gives the product color and texture, as well as protects it from external factors.

| Perforation warranty | 20 years |

| Delamination warranty | 10 years |

MATERIAL ADVANTAGES AND PROPERTIES

| Type and mass of metal coating on both sides | Z 225-275 [g/m²] / ZM 100-140 [g/m²] |

| Environmental classification according to EN ISO12944-2 | C3 |

| Coating system | 2-layer |

| Organic coating thickness, side A | 25 [µm] |

| Reaction to fire | A1 |

| Resistance to external fire | B roof (t1), B roof (t2), B roof (t3) |

MAIN COLOR CHART

-

RAL 1015

RAL 1015 -

RAL 3005

RAL 3005 -

RAL 3009

RAL 3009 -

RAL 6005

RAL 6005 -

RAL 6020

RAL 6020 -

RAL 7000

RAL 7000 -

RAL 7004

RAL 7004 -

RAL 7016

RAL 7016 -

RAL 7035

RAL 7035 -

RAL 8004

RAL 8004 -

RAL 8017

RAL 8017 -

RAL 9005

RAL 9005 -

RAL 9006

RAL 9006 -

RAL 9007

RAL 9007 -

RAL 9010

RAL 9010 -

PE RR 23

PE RR 23 -

PE RR 32

PE RR 32

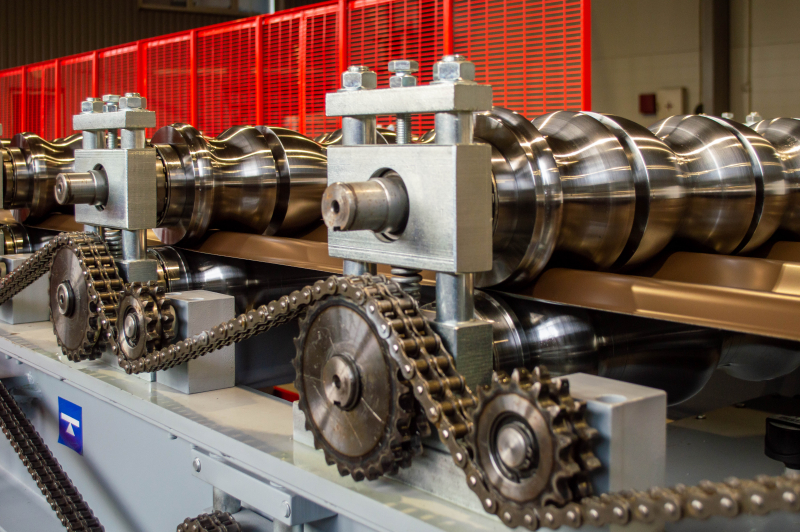

The latest, most modern production lines of 2023!!!

In 2023, we installed a new line for the production of metal tiles of various profiles and sizes in Riga (Latvia).

RKF Lebens is one of the largest companies in the Baltics, offering a wide range of high-quality products that meet the latest requirements, produced on modern production lines manufactured in 2023. Our employees have been working on product quality for private homes and industrial construction for more than 20 years. We fulfill dreams of the ideal home.

Attention!

1. The length of profile sheets is made according to the dimensions given by the customer.

2. Delivery and unloading are recommended with specialized transport.

3. Metal roof coverings in packaging are recommended to be stored for no more than 2 (two) weeks.

For the production of its products, LeBens uses high-quality steel from the world's leading manufacturers.